Bathtub Curve In Maintenance

15 11 is perhaps the most famous graphical representation in the field of reliability plotted is the failure rate h t versus time the resulting curve describes not only the behavior of engineering components but also the lifetimes of human populations.

Bathtub curve in maintenance. The bathtub curve is often quoted in texts about maintenance. Jake blough chief technology officer for service express explores the connection between the bathtub curve theory and data center equipment reliability and maintenance. Bathtub curve kurva bak mandi perencanaan rekayasa arif febriyanto nim 07 256992 tk 33451 jurusan teknik elektro fakultas teknik universitas gadjah mada yogyakarta 2010 abstrak dalam teknik reliabilitas kurva bak mandi digunakan untuk mengetahui tingkat kegagalan dari suatu produk yang dilihat berdasarkan waktu. Wilkins retired hewlett packard senior reliability specialist currently a reliasoft reliability field consultant this paper is adapted with permission from work done while at hewlett packard.

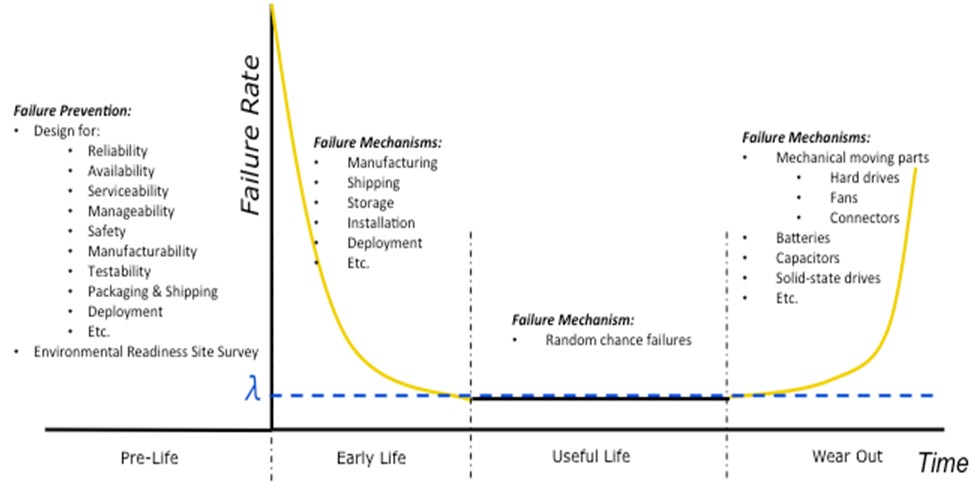

Harness the power of iot to monitor asset health facility condition and track downtime in real time. Figure 1 shows a typical time versus failure rate curve for equipment. It has proven to be particularly appropriate for electronic equipment and systems. The first downward portion of the curve is called an infant mortality phase and shows how.

What is the bathtub curve. Kurva bak mandi mempunyai 3. Reliability bathtub curve review as described in more detail in part one the bathtub curve displayed in figure 1 below does not depict the failure rate of a single item. Some individual units will fail relatively early infant mortality.

As can be seen from the picture above the bathtub curve has three main features. The bathtub curve and product failure behavior part one the bathtub curve infant mortality and burn in. A bathtub curve is a visual of the failure rate of a product over time that maps out three periods that an asset experiences within its lifetime. The second part is a constant failure rate known as random failures.

The first part is a decreasing failure rate known as early failures. This is the well known bathtub curve which over the years has become widely accepted by the reliability community. The bathtub curve named for its shape and shown in fig. Over a certain product lifetime the bathtub curve shows how many units might fail during any given phase of a three part timeline.

It is claimed to represent the failure rate of a population of components systems. Perhaps a useful place to start is with a look at the bathtub curve. Instead the curve describes the relative failure rate of an entire population of products over time. The bathtub curve is a type of model demonstrating the likely failure rates of technologies and products.